- Home

- About Us

- Our Products

- Industry We Serve

- Quality

- Gallery

- Contact us

Get Your Free Quote…!

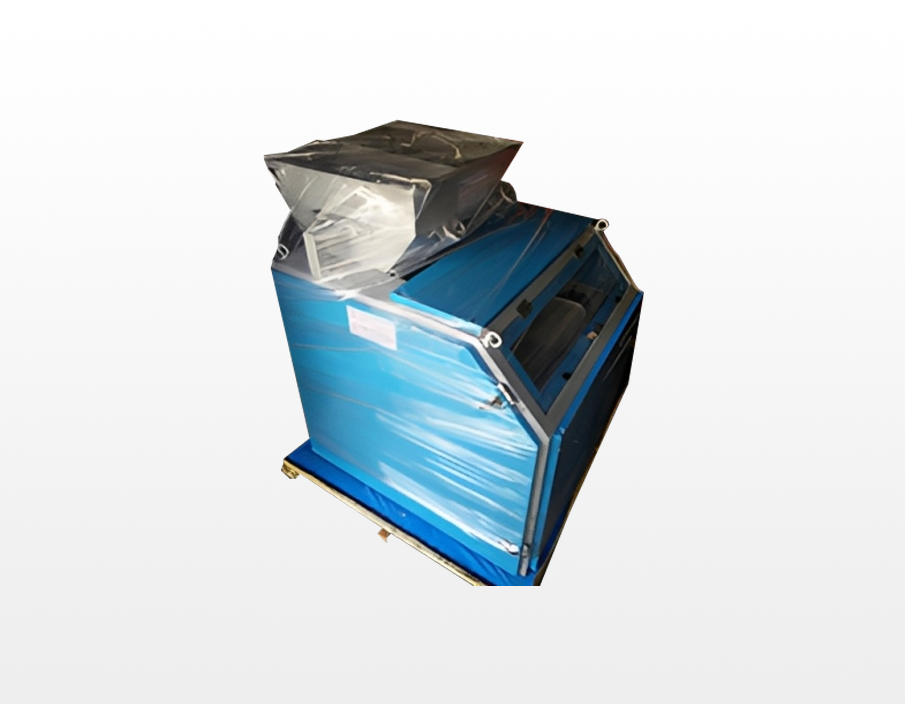

The magnetic roller separator mainly comprises of feed hopper, vibratory flow controller, magnetic roll, Kevlar belt, tail pulley, gear drive, discharge chute, M.S housing etc. Please refer the attached image. Vibratory flow controller helps to control the flow of material as per requirement. The magnetic roller assembly consists of one magnetic roller, tail pulley & Kevlar belt. Each tail pulley is driven by directly shaft mounted gear drive.

There can be multiple roller assemblies arranged one above the other to make multistage system. There is a splitter at the end of each magnetic roller to separate magnetic & non magnetic material. The entire roll assembly along with the cantilever arm, along with the other parts and subsystems are mounted on a rigid heavy duty rectangular tube structure. Entire machines have got a M S paneling duly powder coated and is provided with outlet for dust collection.

InquiryMagnetic Roller Separator is a type of magnetic separation equipment designed to remove ferrous contaminants from materials conveyed in a conveyor belt. The system consists of a series of magnetic rollers that are placed at specific intervals along the conveyor belt. As the belt moves, the magnetic rollers attract and capture the ferrous particles and hold them against the belt until they reach the end of the conveyor where they can be collected and removed.

The Magnetic Roller Separator is suitable for various industries, including mining, quarrying, recycling, ceramics, plastics, and food processing. It can efficiently remove ferrous particles such as bolts, nuts, nails, wires, and other metal debris from the material being conveyed, preventing damage to downstream equipment and ensuring product purity.

Shree Vishwakarma Magnets is a prominent manufacturer, supplier, and exporter of Magnetic Roller Separator for Conveyor Systems in India. They offer a range of models with different specifications to meet various application requirements.

Put ON all stages of assemblies starting from bottom assembly first & then middle & then top. Start the vibratory feeder & regulate the flow of material through hopper outlet. Synchronize the RPM of all stages of assembly with VFD unit with that of vibratory feeder for smooth uniform layered material flow over the rollers

The rotating magnetic roller separates the iron contamination from the material with the help of splitter. The iron contamination can be collected in a tray. The good material can be collected in the bags from the discharge chute. As it is a self cleaning magnetic system it reduces the man power required during operation & hence increases the productivity.